Ningbo Shitai Precision: Intelligence Powers Future, Precision Crafts Excellence

Amidst the surging tide of intelligent manufacturing, Ningbo Shitai Precision Machinery Co., Ltd. stands at the forefront as a premier provider of core precision component solutions, specializing in non-standard precision machining to drive global high-end manufacturing innovation. We deeply integrate digitalization, intelligentization, and intelligent automation technologies to precisely meet the dynamic demands of cutting-edge industries—including artificial intelligence (AI), new energy vehicles, low-altitude economy, and ground automation—delivering highly reliable, high-precision core components to global clients.

Shitai Precision’s excellence stems from nearly three decades of profound technical expertise and forward-thinking strategic vision. We regard technology as our lifeblood, making continuous process innovation and core value creation for customers our competitive edge. Committed to advancing our "Digital-Intelligent" strategic transformation, we aim to achieve industry leadership in digital application depth, intelligentization level, and Gross Domestic Product per Worker (GDF) within precision manufacturing, establishing an efficient, flexible, and zero-defect benchmark for smart production. Our leading precision machining technologies, specialized process capabilities, and a dedicated team of professional and innovative talents form a solid foundation for sustainable future growth.

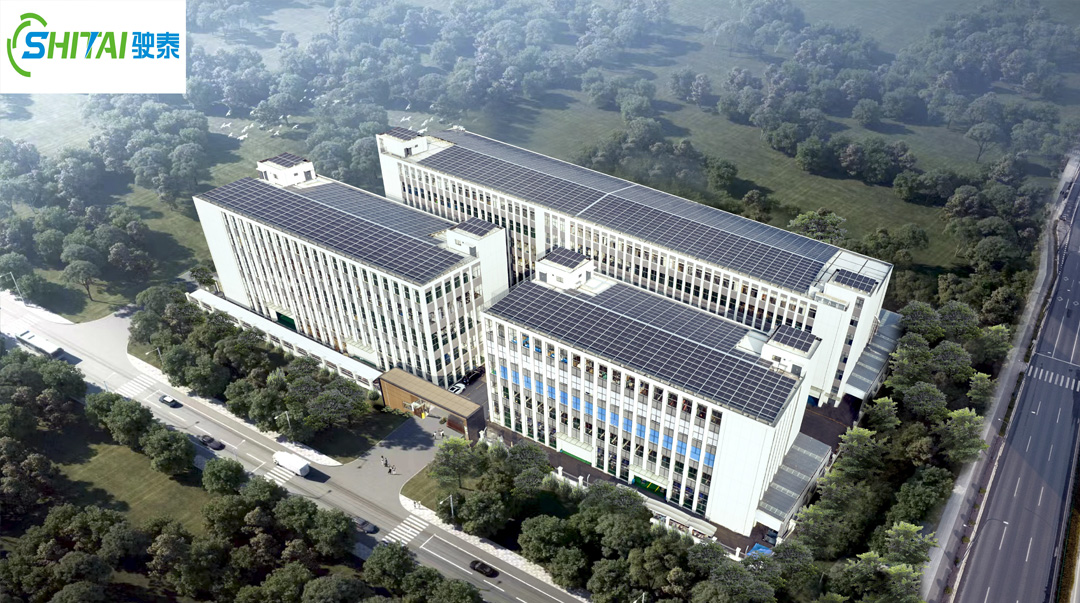

Robust intelligent manufacturing capabilities are the cornerstone of Shitai Precision’s commitment fulfillment. We persistently invest in the future, incorporating top-tier high-precision equipment from Germany, Japan, Switzerland, and intelligent inline inspection systems to build digitally-driven modern production lines. Strict adherence to the IATF 16949:2016 international automotive quality management system ensures end-to-end product excellence and stability. Housed in a modern production base spanning over 30,000 square meters, we possess the capacity for large-scale manufacturing and agile delivery of 500 million precision shafts, mechanical parts, hardware components, aluminum parts, and die-castings annually.

Shitai Precision’s ingenuity empowers the innovative pulse of global industries. Our precision components serve as critical "industrial joints" and "neural units," widely applied in:

The Mobility Revolution: Core parts for new energy vehicle powertrains, precision structural components for low-altitude aircraft, and high-efficiency transmission systems for ground automation equipment.

The Smart-Connected World:High-efficiency thermal management/high-speed connectors for AI servers and devices, key precision components for ICT infrastructure.

Green Quality Living: Core assemblies for next-gen energy-efficient commercial and household appliances, optimized components for intelligent ventilation and heat dissipation systems.

High-End Equipment: Critical parts for precision medical devices, core components for modern high-end agricultural and landscaping machinery.

As a trusted partner within the global high-end industrial chain, Shitai Precision’s products are exported worldwide to markets including the Americas, Europe, Japan, Korea, India, and Southeast Asia. We maintain long-term strategic partnerships with numerous world-renowned enterprises, proudly supplying core precision components to industry leaders such as Bosch, Siemens, Mercedes-Benz, BYD, NVIDIA, John Deere,among others.

Shitai Precision is redefining the boundaries of possibility in precision manufacturing through digital-intelligent transformation. Guided by innovation and master craftsmanship, we are committed to becoming a pioneering force in intelligent manufacturing and look forward to collaborating with global partners to co-create a brilliant new chapter for the future of smart industry!

2011

Having been deeply involved in the precision machinery industry for 20 yeas,SHITAI was established in 2011 with a comprehensive accumulation of technology and experience

2012

Started cooperation with Askoll and marched into home appliance market

2013

Obtained ISO/TS 16949 quality certification

2014

Passed the customer audit by Ebmpapst and marched into automobile ,electric motor and wind motor market

2015

Passed the customer audit byJohn Deere and marchedintoagriculture machinery market

2017

Moved to 8,000 square meters new factory buildings

2018

Obtained IATF 16949:2016 quality certification

2019

Be awarded ASKOLL Corporate Global Excellent Supplier

2020

Obtained 12 patents on automobile shaft, power shaft and various kinds of shafts

2021

Created new energy automobile motor pump shaft automatic intelligent production Line

2022

Seted up Dalian office, committed to the development of Japanese customers and new energy automobile customers

2023

New plant plan, cover an area of 30,000 square meters

2024

The new production base has been put into use,covering an area of 30000 square meters. Market-oriented large-scale, modern, digital, automatic intelligent production base